CATEGORIES

FEATURED PRODUCTS

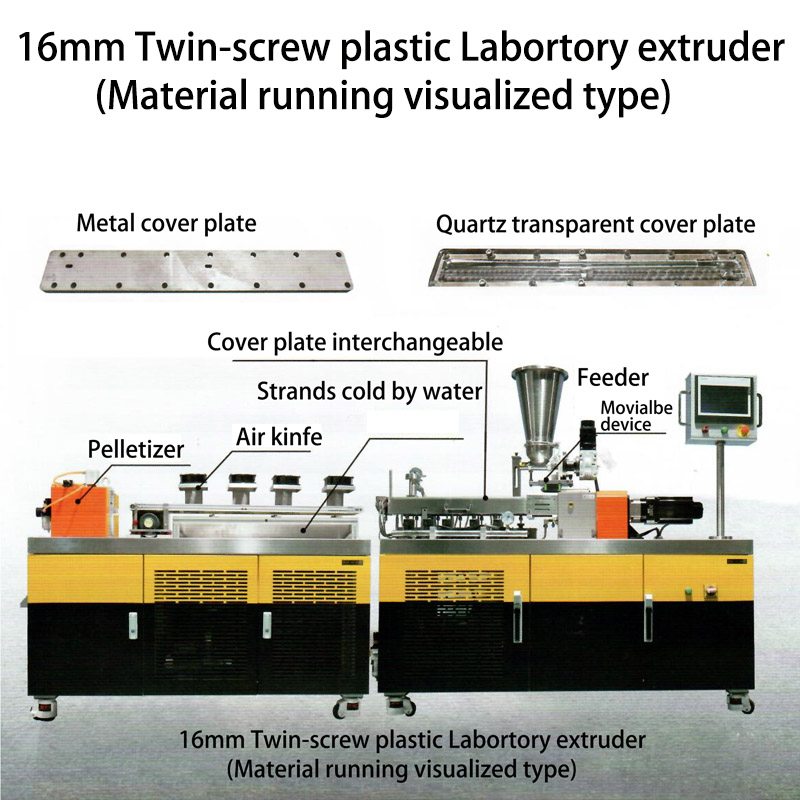

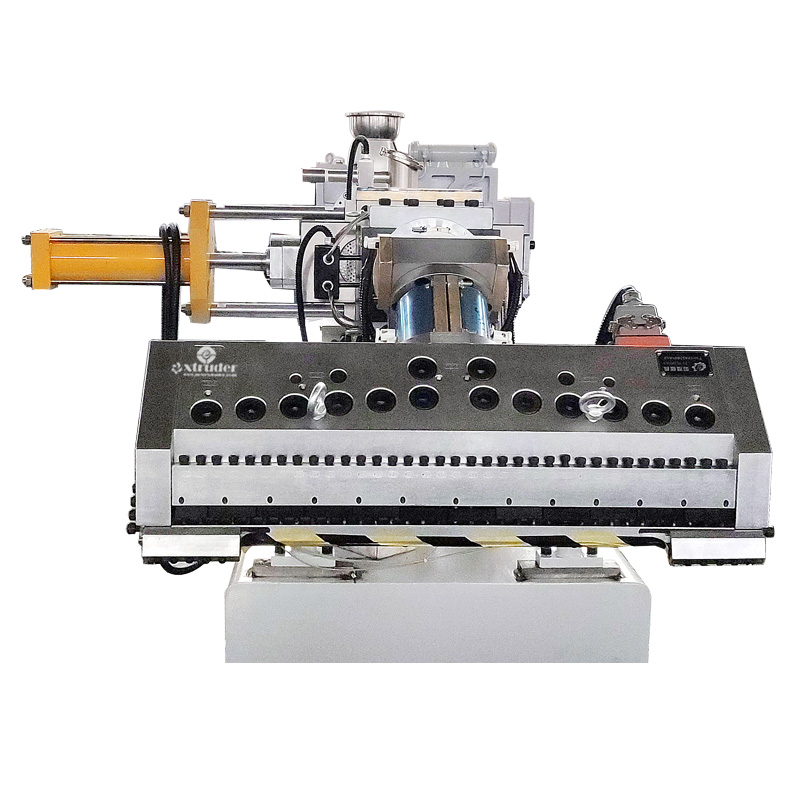

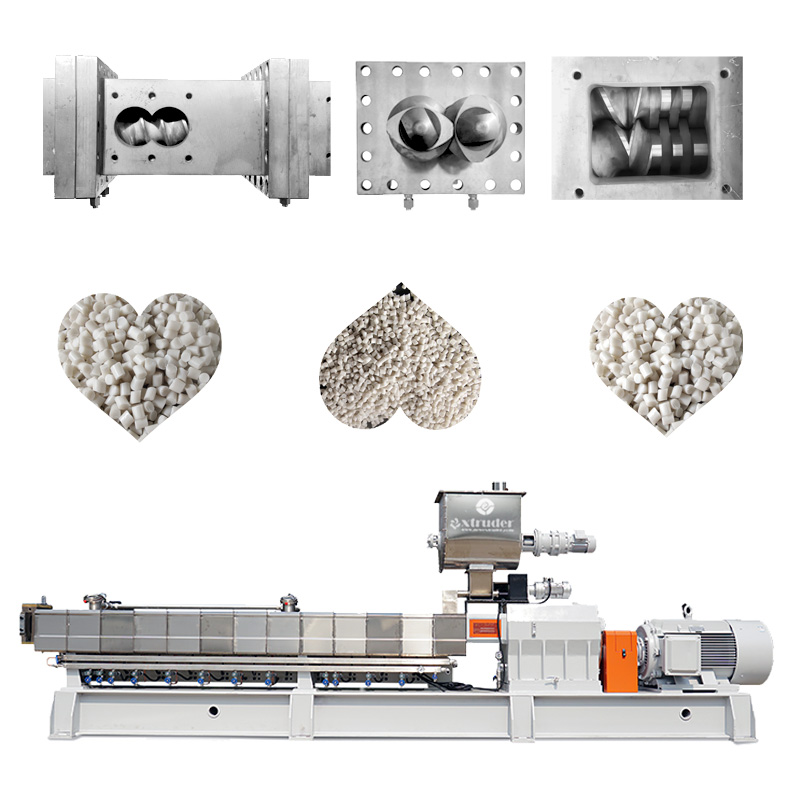

SHJ Series of Plastic modification Twin-screw extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

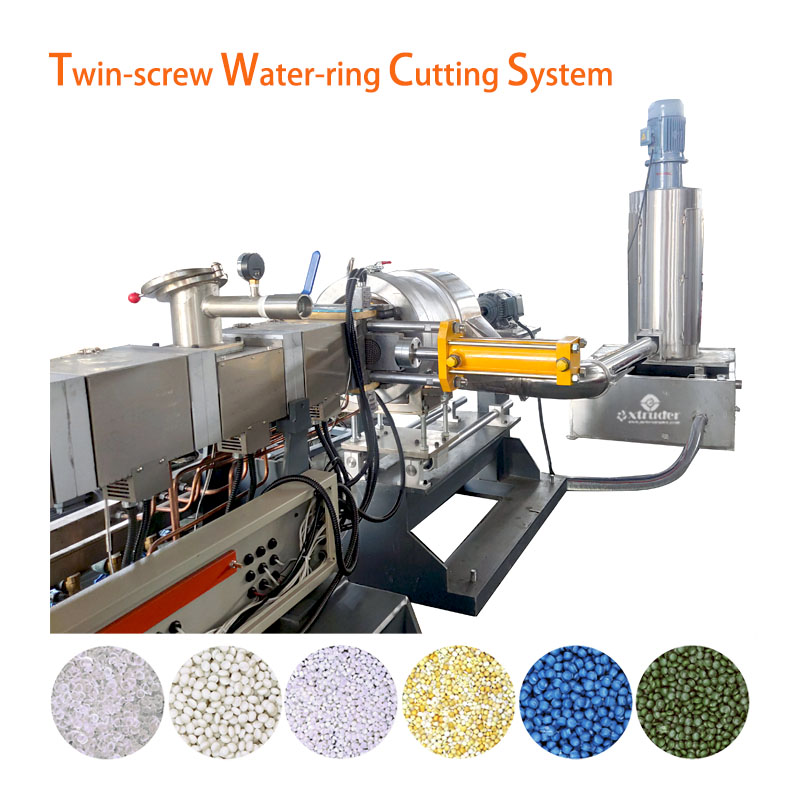

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder

Recycling plastic regranulation extruder machine PE PP PET ABS recover granulation system recycling and reusing extruder

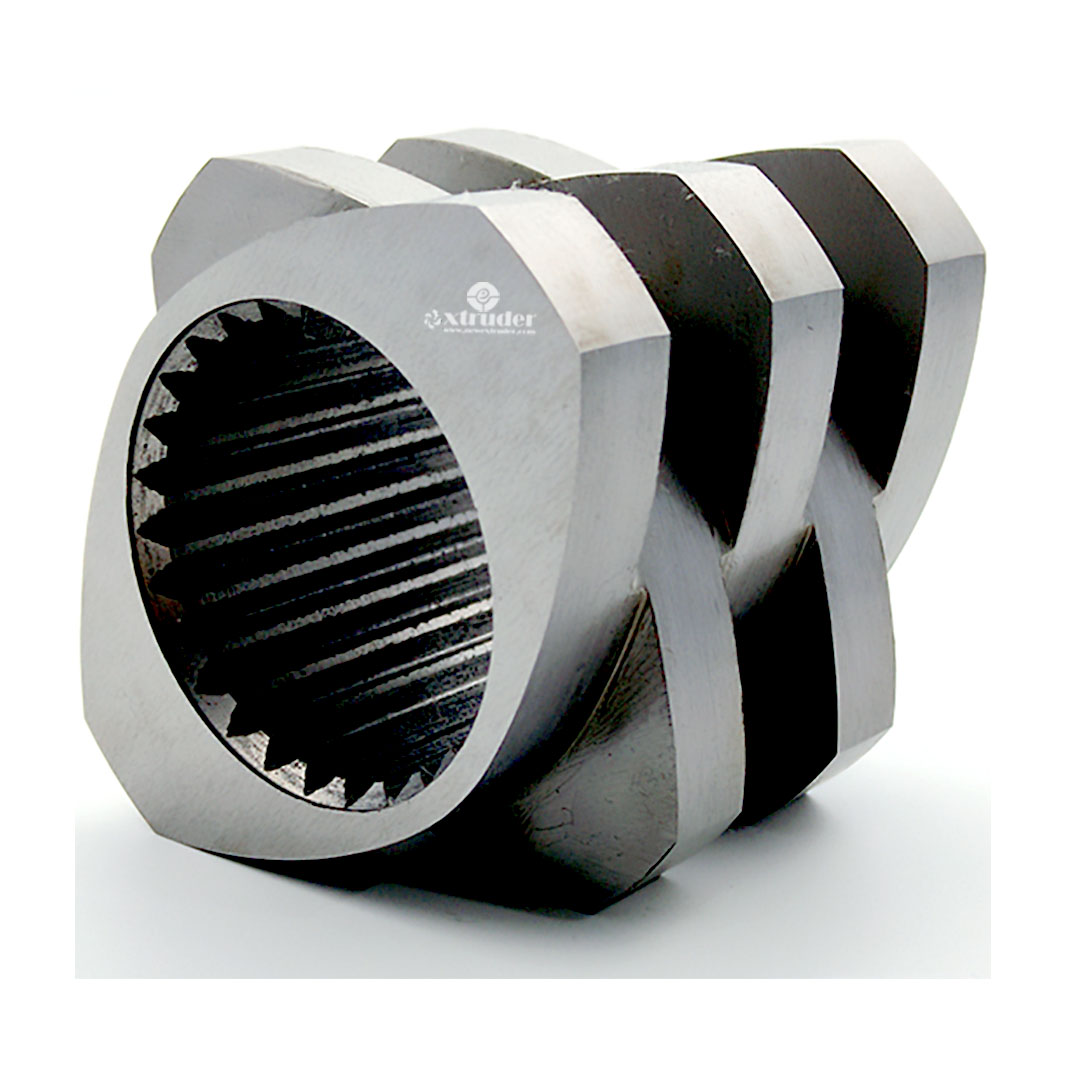

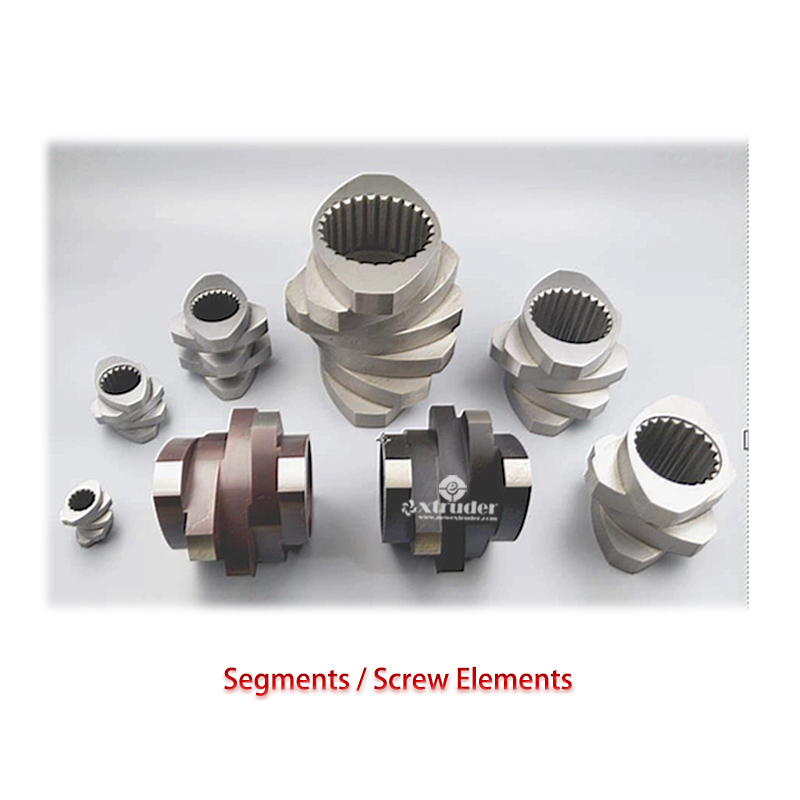

Twin-screw element segments material transferring mixing compounding shearing extrusion function

SHORT DESCRIPTION:

Spare parts for twin screw plastic extruder

- Product Detail

- Our machine can process the following materials:

- Product Tags

Screw-elements (screw segments) for twin-screw plastic extruder machine

Spare parts for twin screw plastic extruder

Different kinds of twin screw elements (segments) for material transferring, mixing, compounding, shearing and extrusion.

HS CODE: 8477.9000

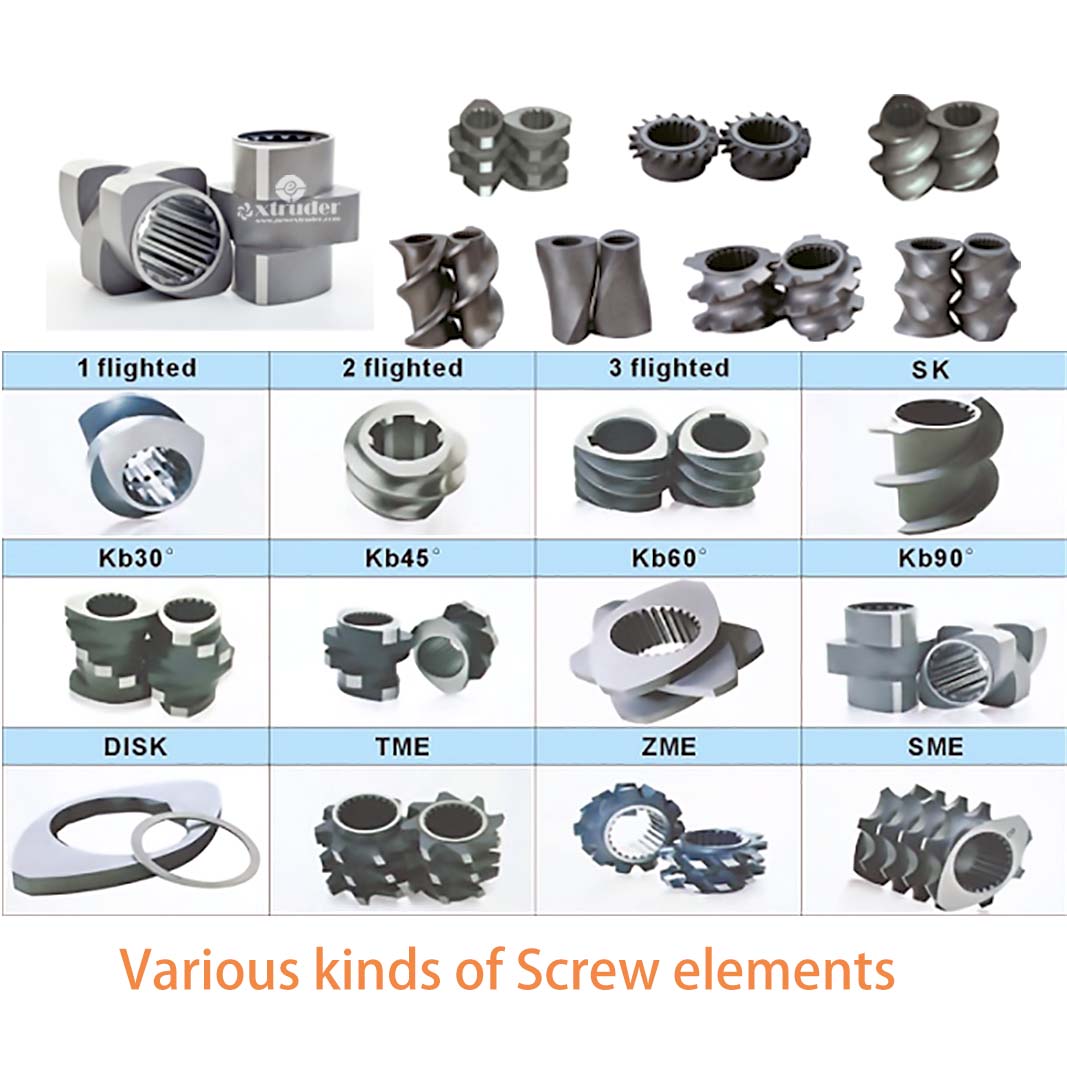

The species of Screw-elements (screw segments) for twin-screw extrusion machine

There are some species of Co-rotating parallel twin-screw plastic extruders: formulated material conveying segments, Kneading screw segments, shearing & mixing segments, toothed discs, and other specially designed screw elements(screw segments). According to different materials, the screw segments (screw elements) components are specially combined to performance to the modification requirements of different materials of different customers;

Twin screw extruder: Screw extruder is a machine that can focus a series of chemical basic unit processes, such as solid material conveying, pressurization, melting, air exhaust, dehumidification, melt conveying and vacuum pumping, and other physical processes on the screw inside the extruder barrels. Compared with the single screw extruder, the twin-screw extruder can make the melt more fully mixed, so it is widely used in the modification of plastics, such as color masterbatch, functional masterbatch, filling masterbatch, degradable plastic masterbatch, and other applications.

|

|

Screw-element segments are also classified into several categories according to the material:

1, single head thread element: generally used in the feeding section, has a high solid transfer capacity, the role used to transport the poor flow of materials and improve the extrusion amount is limited by the feeding amount.

2, double head thread element: under the same screw speed, can provide a lower shear rate and is suitable for low loose density powder glass fiber shear sensitive materials. The standard thread components are generally double head design, there are screw sleeves for conveying materials, and there are shear, mixing, and mixing terminal components to make the molecular chain rearrangement combination of different shapes and functions of the meshing block, shear block, and other special thread components

|

|

3, three screw components: under the same screw speed, can apply higher average shear force and shear rate to the material.

|

|

|

|

The three differences:

1)the output capacity and torque of single-threaded components are greater than the other two, and the mixing characteristics are more than multi-threaded ones;

2)Compared with three-threaded components, two-threaded components can operate at higher speeds and have higher productivity.

3)The three-threaded component has better heat transfer performance than the two-threaded component, which is conducive to physical plasticizing and melting.

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |