NEWS

How to make sure whether an extruder is a good extruder for color master-batch or filler making?

As you know, good plastic color masterbatch and high-filling plastic pellet products need three effective combinations: proper equipment, good formula, and reliable process, all of which are indispensable. But most of the time, because of the unreasonable formula and the lack of process, users and formula engineers will blame equipment problems. In many cases, after effective communication between the formula engineer and our equipment engineer, the problems encountered will be solved without adjusting the formula and only adjusting the process. Our products pay more attention to the dispersion and distribution of the final plastic color mother to meet the actual needs of users.

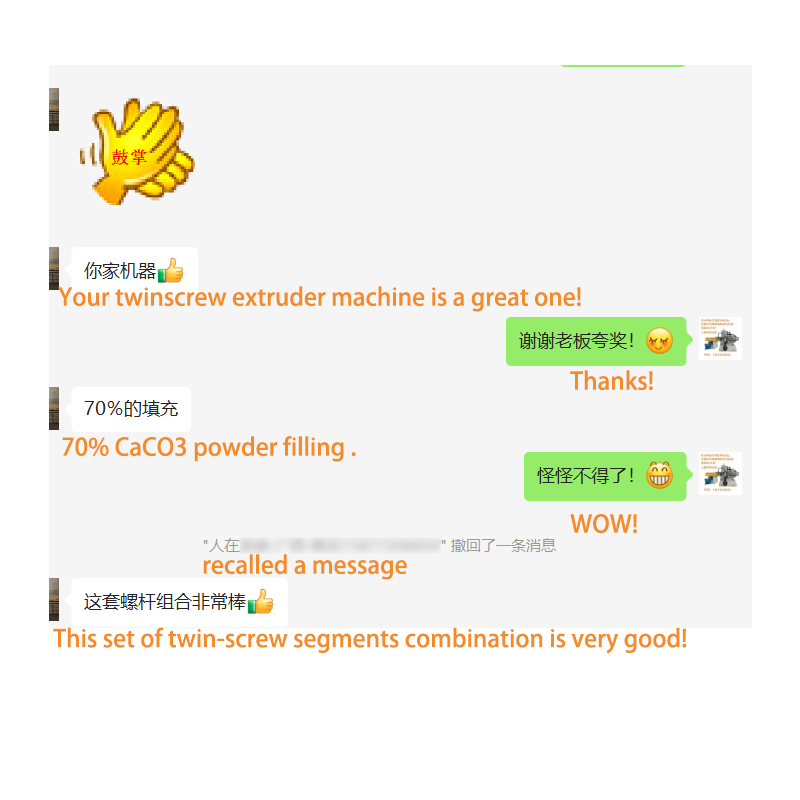

last month, a customer was equipped with two specially designed twin-screw extruder granulators for making calcium carbonate powder high-filling color masterbatch. The models are SHJ35B and SHJ65B . After a period of production, the customer specially sent his color masterbatch granules production video and product pictures to praise our twin-screw plastic extruder machine (granulator) for its good finished products. The dispersion and distribution of the particles are particularly satisfactory, said that in the past to add at least 5% of the resin and used high-grade calcium carbonate powder to make good finished particles; With the use of our twin-screw extruder granulating machine, without affecting the quality of the product, the amount of resin can be less, the amount of calcium carbonate powder filling can be added more than before. That is to say, in the case of the same quality in the same level, the cost can be further reduced, and there is a better price competitive advantage, the engineers have told me: this is unimaginable in the past.