CATEGORIES

FEATURED PRODUCTS

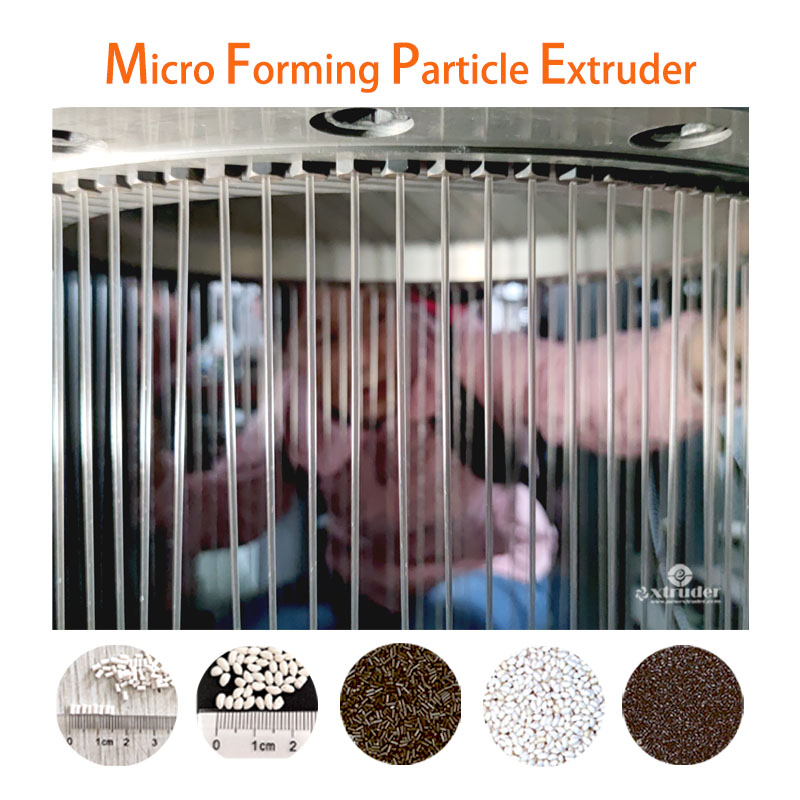

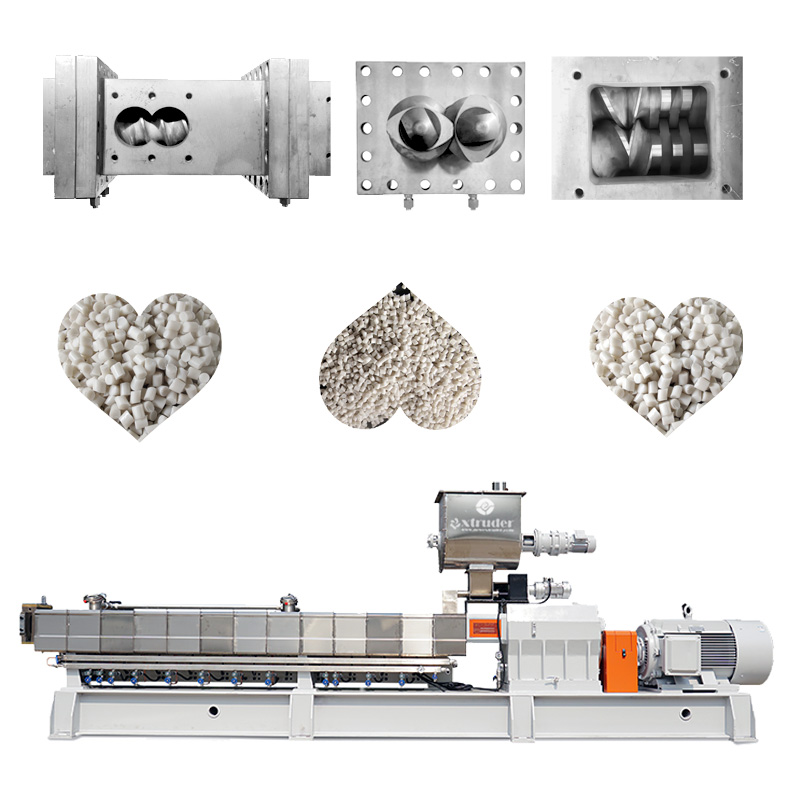

SHJ Series of Plastic modification Twin-screw extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

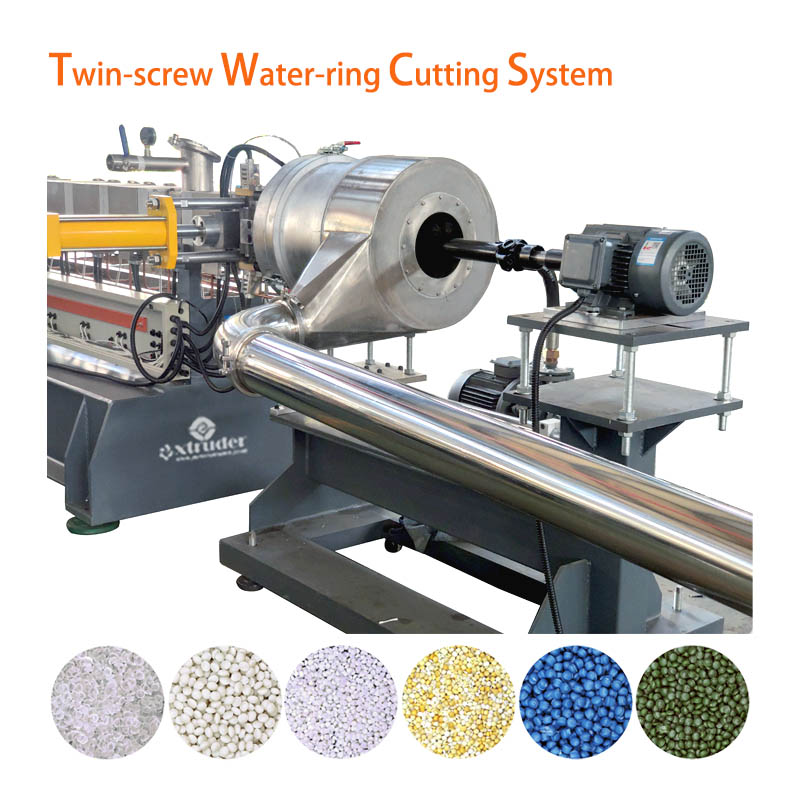

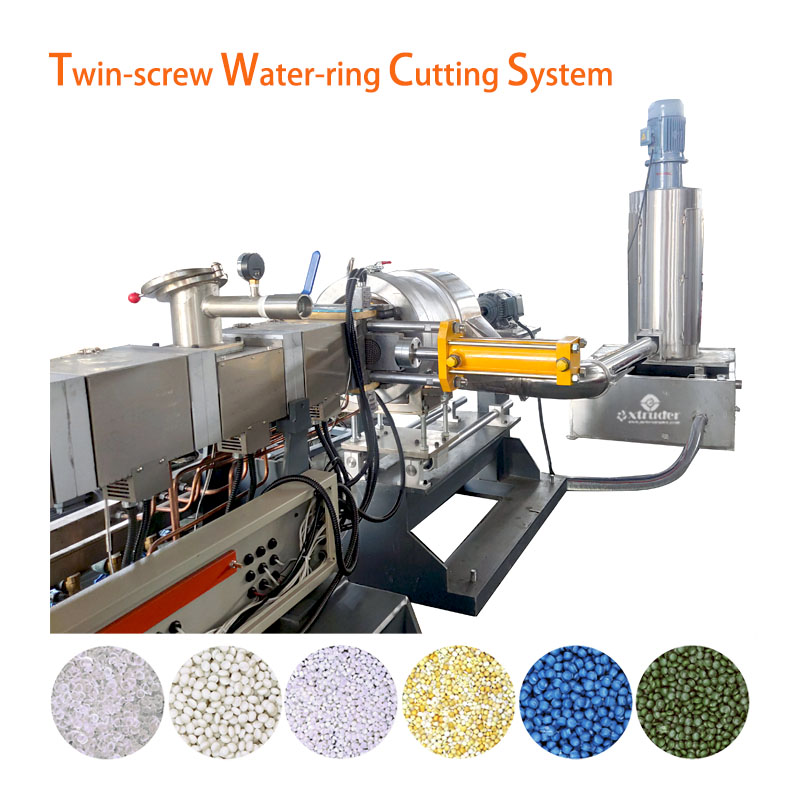

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder

Recycling plastic regranulation extruder machine PE PP PET ABS recover granulation system recycling and reusing extruder

PIN FIXING & REMOVING MACHINE FOR PCB CCL BOARD

SHORT DESCRIPTION:

PIN FIXING & REMOVING MACHINE FOR PCB CCL BOARD This machine is for multi-pieces of PCB pin fixed or removed each other for driling or doing other treatment.

- Product Detail

- Our machine can process the following materials:

- Product Tags

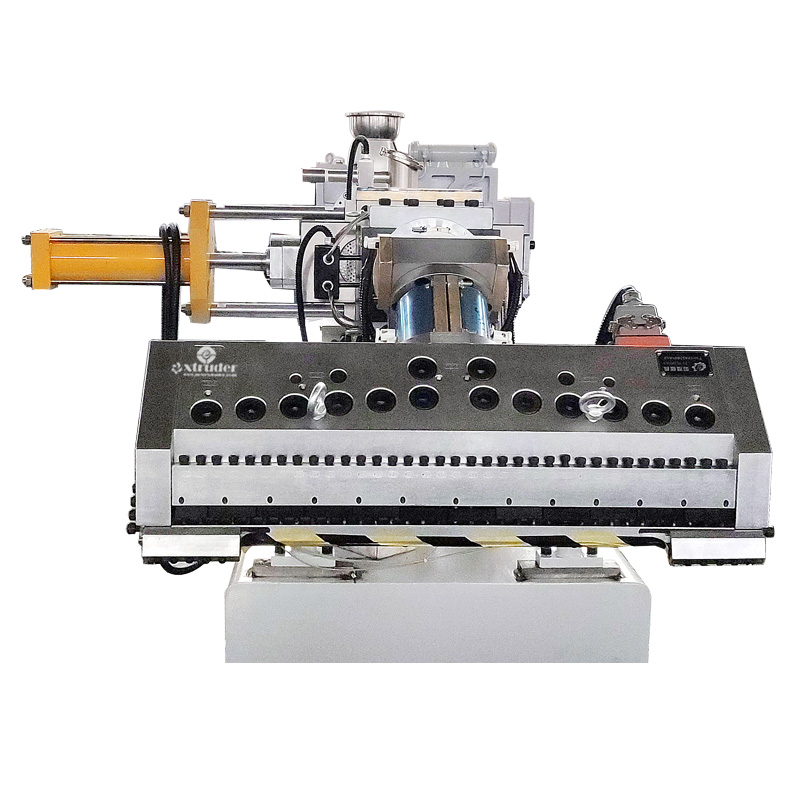

PIN FIXING & REMOVING MACHINE FOR PCB CCL BOARD

PIN FIXING & REMOVING MACHINE FOR PCB CCL BOARD

This machine is for multi-pieces of PCB pin fixed or removed each other for driling or doing other treatment.

HS CODE: 8465920000 OR 8479899990

Brand: JZ

|

|

Technical Parameter for PIN FIXING & REMOVING MACHINE FOR PCB CCL BOARD

The machine is specially designed for machining positioning holes before CNC drilling press drills holes and the drill press is used for producing double-sided printed circuit boards.

The machine is capable of holes drilling, pin fixing and removing automatically.

Distance of two positioning holes: Max. 500mm/ Min. 90mm

Printed board size: Min. 100mm*100mm

Rotating speed of main shaft: 20,000 rpm – 30,000 rpm (steplessly adjustable)

Hole diameter: Φ3.0—Φ4.5mm

Spring chuck of main shaft: Φ3.175

Electrical supply and power: single phase 220V/50HZ,1.0KW

Compressed air: air pressure 0.5mPa, air consumption: 0.15m³/second

We also made automatic type for PCB PIN INSERT & REMOVE MACHINE

|

|

Technical Parameter for PIN FIXING & REMOVING MACHINE FOR PCB CCL BOARD

The machine is specially designed for machining positioning holes before CNC drilling press drills holes and the drill press is used for producing double-sided printed circuit boards.

The machine is capable of holes drilling, pin fixing and removing automatically.

Distance of two positioning holes: Max. 500mm/ Min. 90mm

Printed board size: Min. 100mm*100mm

Rotating speed of main shaft: 20,000 rpm – 30,000 rpm (steplessly adjustable)

Hole diameter: Φ3.0—Φ4.5mm

Spring chuck of main shaft: Φ3.175

Electrical supply and power: single phase 220V/50HZ,1.0KW

Compressed air: air pressure 0.5mPa, air consumption: 0.15m³/second

We also made automatic type for PCB PIN INSERT & REMOVE MACHINE

TAGS : PCB CCL PIN FIXING & REMOVING PCB PIN FIXING MACHINE PCB PIN REMOVING MACHINE PCB CCL PIN FIXING & REMOVING MACHINE PCB Equipment Manufacturer

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

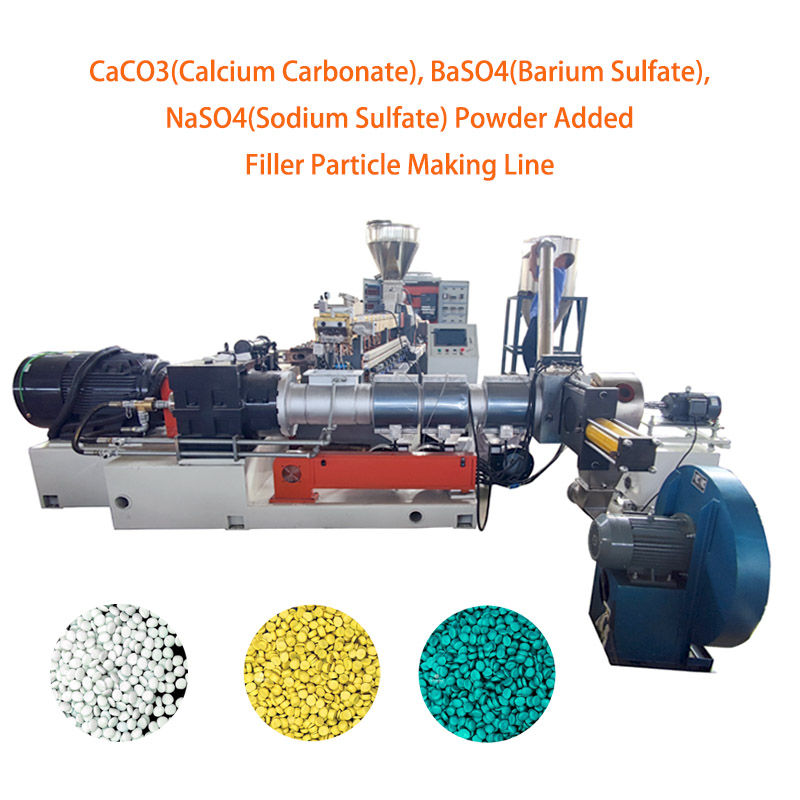

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |