CATEGORIES

FEATURED PRODUCTS

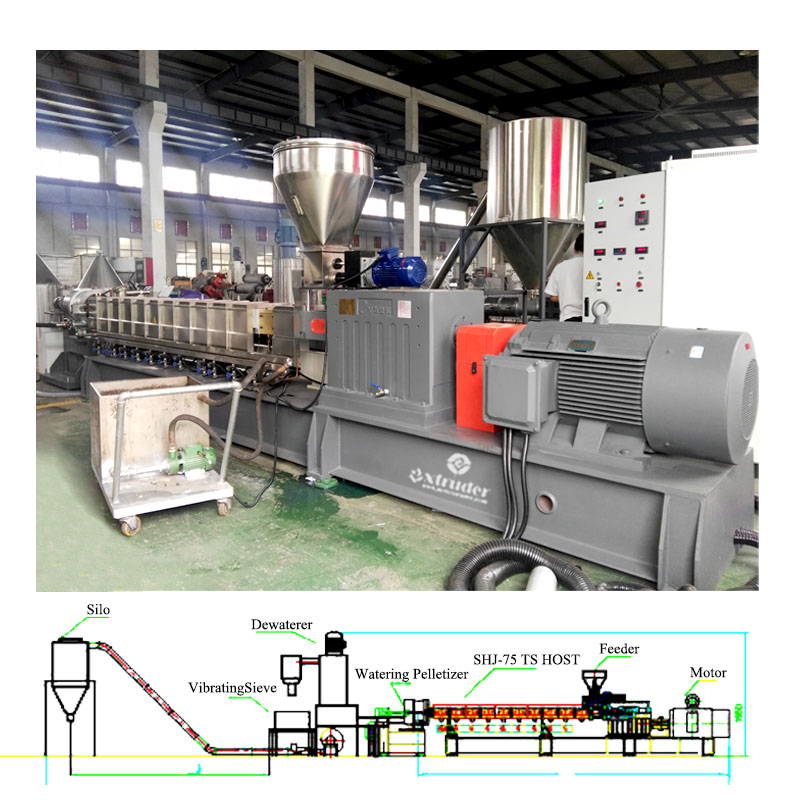

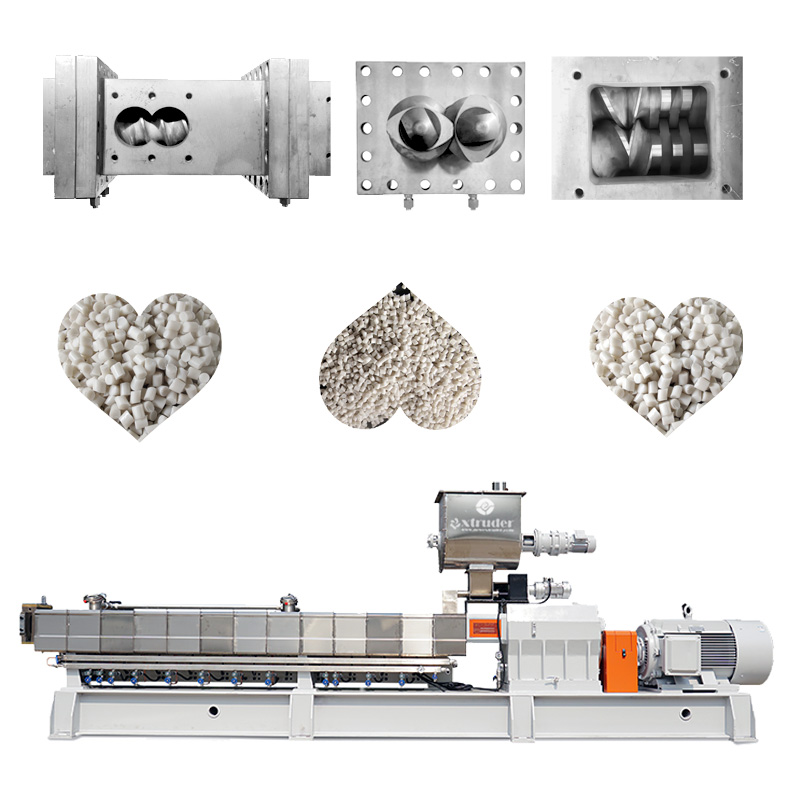

SHJ Series of Plastic modification Twin-screw extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

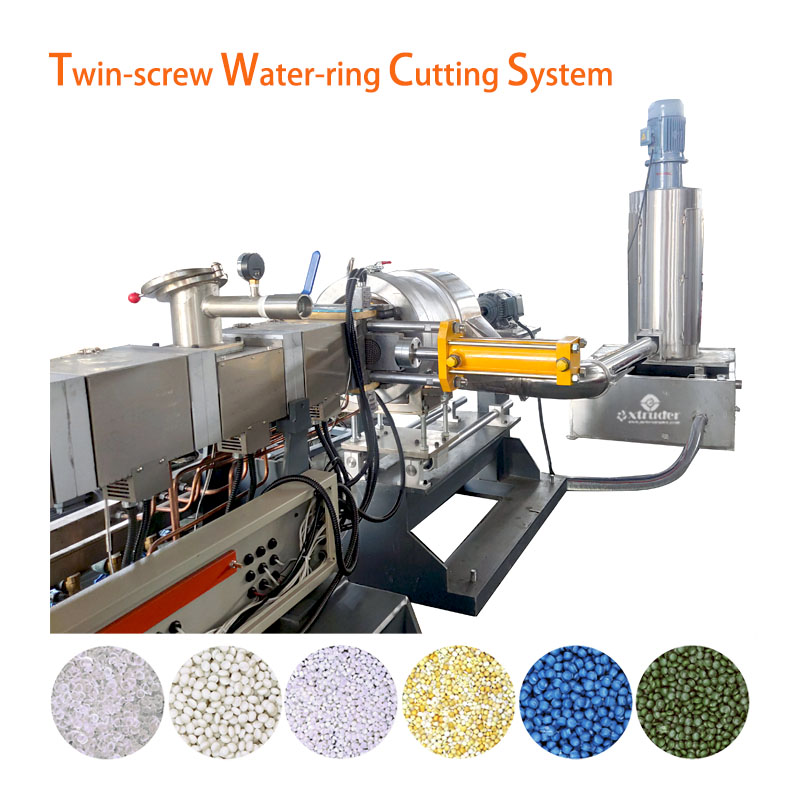

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder

Recycling plastic regranulation extruder machine PE PP PET ABS recover granulation system recycling and reusing extruder

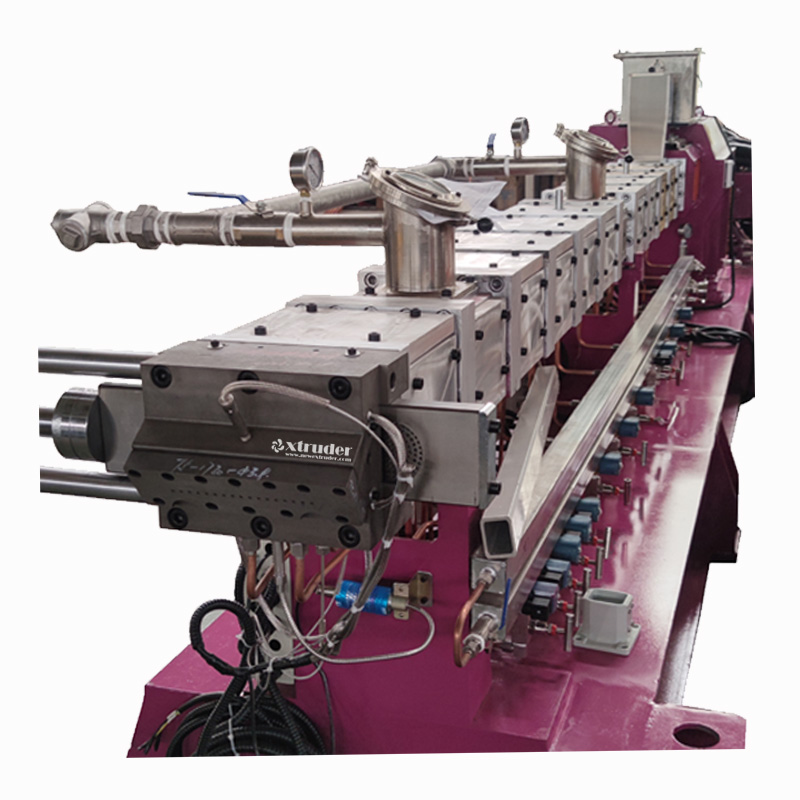

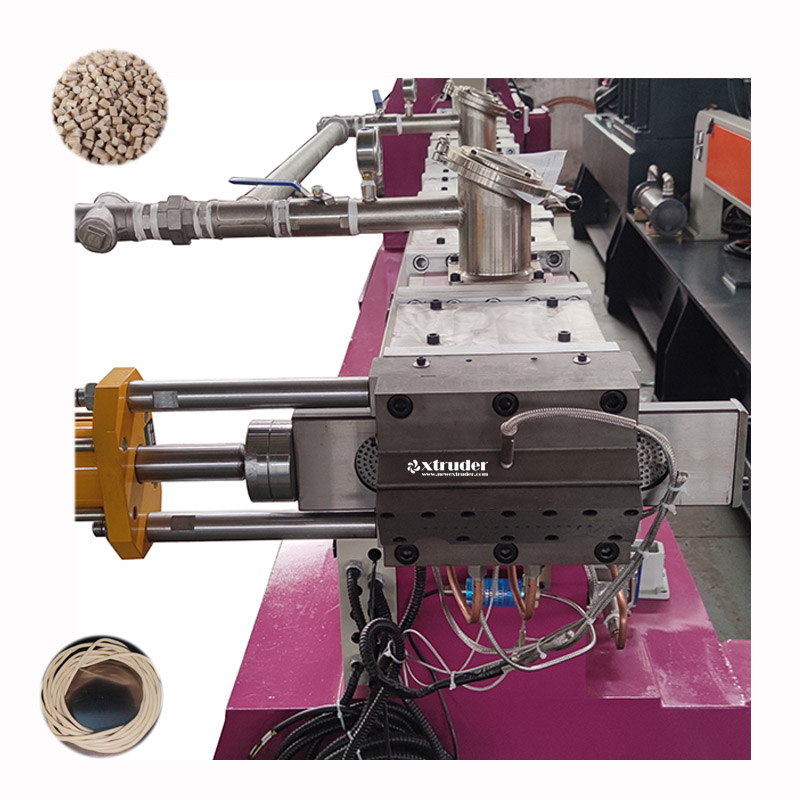

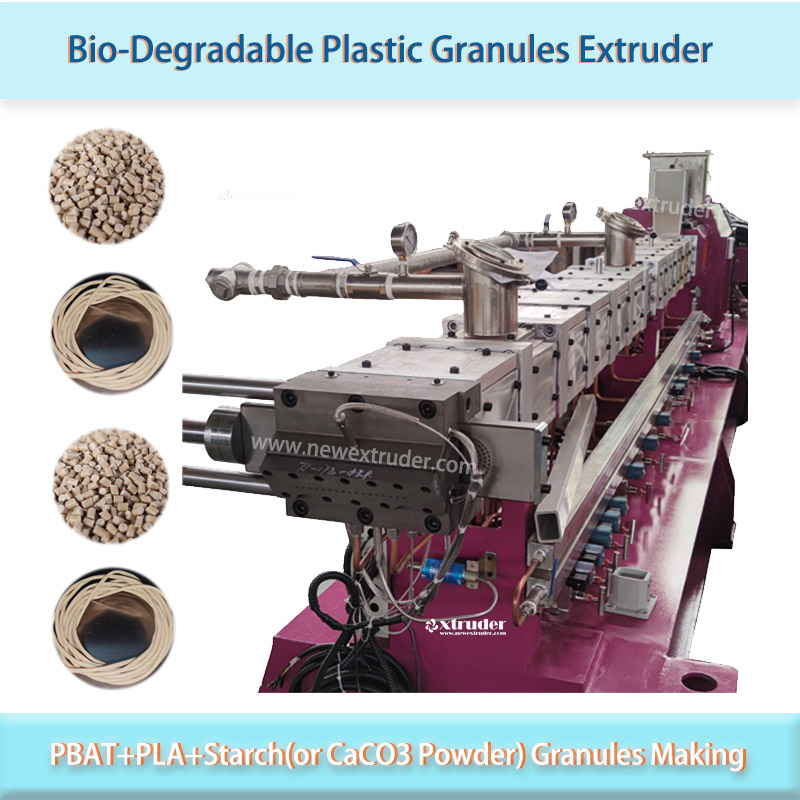

Twin screw plastic extruder Biodegradable PBAT PBS PLA with starch powder or added calcium carbonate powder

SHORT DESCRIPTION:

Twin screw plastic extruder Biodegradable PBAT PBS PLA with starch powder or added calcium carbonate powder This machine line is for BIO degradable PBAT, PBS, PLA & other plastic granule-making.

- Product Detail

- Our machine can process the following materials:

- Product Tags

Twin screw plastic extruder Biodegradable PBAT PBS PLA with starch powder or added calcium carbonate powder

This machine line is for BIO degradable PBAT, PBS, PLA & other plastic granules making.

HS CODE: 8477.2010

Min. Order :1Unit

Making Cycle :45-60 working days after the down payment (deposite) has done.

Payment Terms :T/T in advance

Packing Method :Export standard: wrapping film cover and wooden pallet on the parts’ bottom for forklift using.

Quality Guarantee Period :12 month from the B/L issued date.

Annual Production Capacity :Around 500 Lines

CUSTOMER DESIGN OR OEM :Acceptable

This machine line is for BIO degradable PBAT, PBS, PLA & other plastic granules making.

HS CODE: 8477.2010

Min. Order :1Unit

Making Cycle :45-60 working days after the down payment (deposite) has done.

Payment Terms :T/T in advance

Packing Method :Export standard: wrapping film cover and wooden pallet on the parts’ bottom for forklift using.

Quality Guarantee Period :12 month from the B/L issued date.

Annual Production Capacity :Around 500 Lines

CUSTOMER DESIGN OR OEM :Acceptable

Product Introduction

This machine line is for BIO degradable PBAT, PBS, PLA & other plastic granules making.

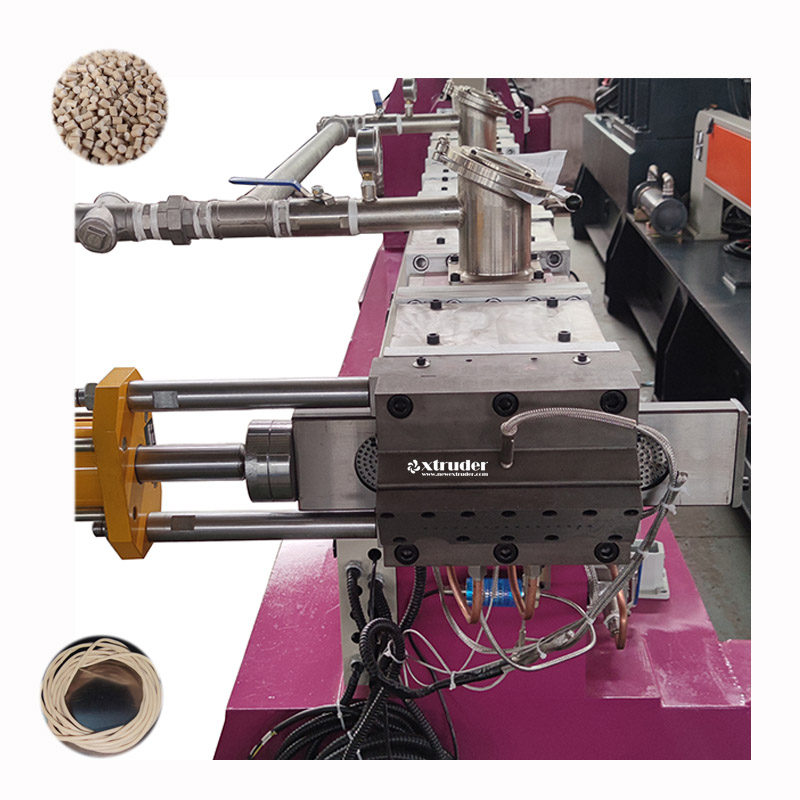

Model: SHJ-65D, SHJ-75D, SHJ-95D

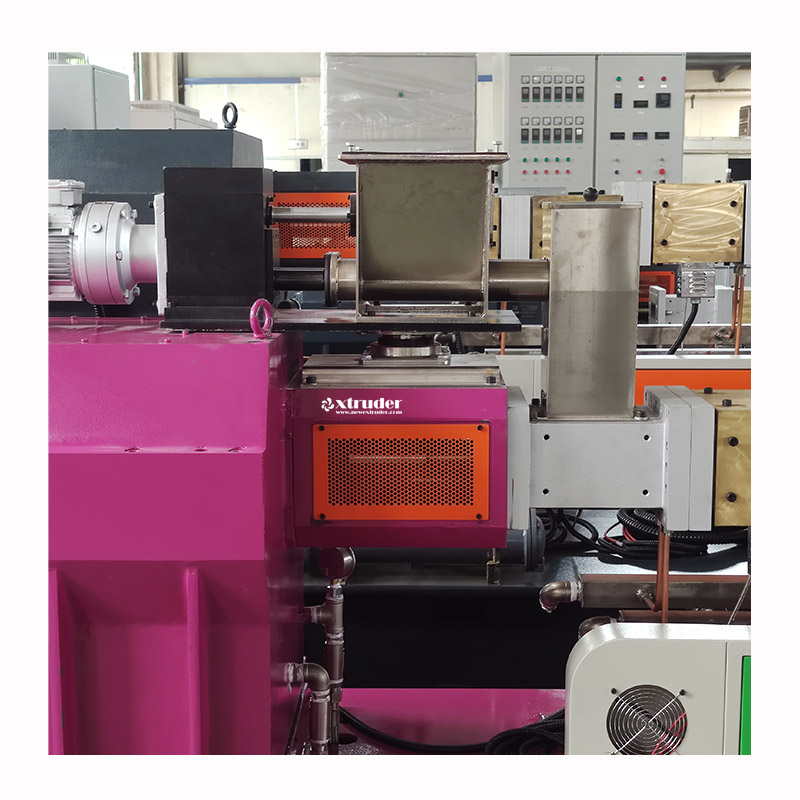

This machine line is for BIO degradable plastic particles making(PBAT/PBS/PLA/PPC/PHA & Etc., if you need special request and pay the extra cost of the parts, it could be equipped vector( loss in weight scale), side feeder, and so on, also it could be set PLC + Touch Screen + Temp. controlling module. We accept customer design and other special request and demands’ machine lines.

Screw Speed: 400rpm and 500rpm

L/D: 48:1; 52:1;

Output Capacity: SHJ-65D: 200-400Kgs/hr SHJ-75D: around 300-600Kgs/hr or over.

Main Motor Power: SHJ65D: 132KW / SHJ75D: 250kw,Wannan brand ( optional: WanNan Brand, Siemens brand, Dazhong brand);

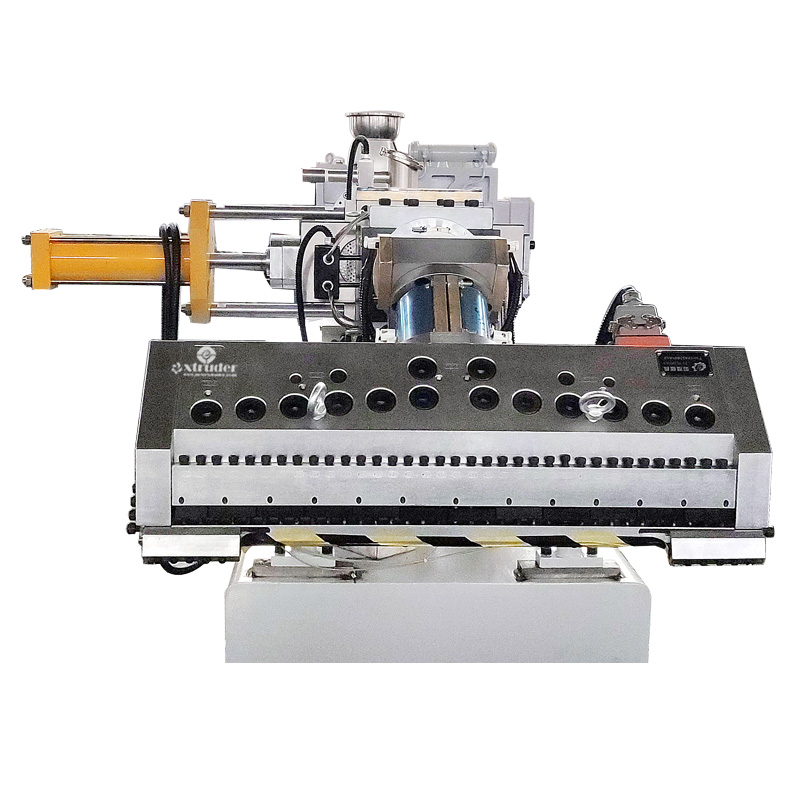

Die Head: Standard type;

Purpuse: BIO degradable plastic granules, Engineering and Etc.;

Heater: Copper casting;

Air cooling chain convoying system or strands bathing water cooled pelletizing system:

Air Knife: 2 Heads type

13 holes, Dia.:4.0, inside hole polished carefully

Whole casting copper heaters,

38CrMoAlA

Air cooling strands belt convoying pelletizing system;

Screen Change (2.2KW motor ) with 6.3L Hydraulic workstation

whole line includs HOST, oil cooling system for gearbox, water cooling system for barrels, vacuum system for barrels, 2.2KW Air knife (two heads), 300 Pelletizer, 500 Vibrating sieve; single stages of air convoying granules transferring system with 1.5 CBM Silo.

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |